Healthier air for remote mining sites

Western Australia | Commercial Building

Problem

A mining company in Western Australia’s Pilbara region was concerned about indoor air quality in one of its remote site offices. The building, constructed from converted shipping containers, was exposed to extreme temperatures, high humidity, and the region’s infamous red dust. Staff reported poor air circulation and discomfort during working hours, particularly as CO₂ levels rose when the office was in use.

The building had been sealed in an effort to reduce dust ingress, but without active ventilation, stale air and humidity were being trapped inside. The client also observed that when the office was left unoccupied, condensation formed on walls and ceilings due to a lack of airflow and climate control, raising the risk of mould growth and long-term structural damage.

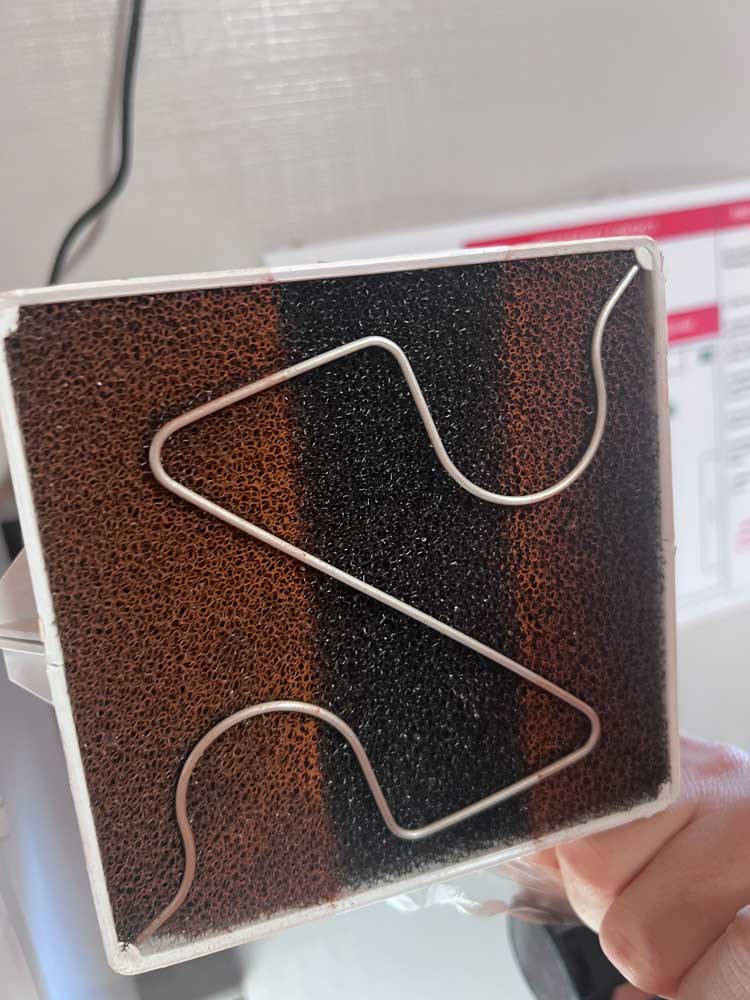

At the start of the monitoring period, filters were installed to assess the particulate load in the space. After just one week, the filters were visibly clogged with red dust, revealing the extent of airborne contaminants that had been circulating unnoticed. This confirmed that the site needed more than passive sealing and cooling—it required continuous, effective ventilation and filtration to maintain air quality and protect both people and equipment.

Proposal

STIEBEL ELTRON recommended installing compact VLR 70 decentralised heat recovery ventilation (HRV) units. These systems are purpose-built for tough environments with space limitations and feature high-performance filters to remove fine dust particles—including the Pilbara’s red dirt—from incoming air.

Plan

Eight VLR 70 units were installed across 188 m² of container office space, accommodating an average of 10 workers. The units were configured to deliver 0.55 air changes per hour (ACH), keeping CO₂ levels below 1000 ppm and meeting the standard for moderate indoor air quality. Each room was fitted with decentralised filtration to ensure clean, breathable air throughout the day.

Execution

The initial installation took place in July 2024, with additional units added in October as demand grew. Each VLR 70 unit delivered up to 280 m³/h of airflow and included advanced filtration to trap airborne contaminants—particularly red dirt and fine particulate matter that easily enter semi-sealed container offices.

Findings:

- PM2.5 and PM10 levels dropped to just 1 μg/m³, despite heavy external dust

- Humidity remained stable at 39%, reducing the risk of mould

- Air quality remained high, even when offices were unoccupied

- Red dust was significantly reduced, lowering cleaning needs and protecting electronics

- Energy-efficient operation supported cooling without driving up costs

Summary

STIEBEL ELTRON’s VLR 70 HRV units provided a compact, energy-efficient ventilation solution that improved air quality and reduced condensation in one of Australia’s toughest environments. This success has led to further studies with the client exploring similar applications in modular housing, where air quality issues persist.

| Products | VLR 70 decentralised heat recovery ventilation |